Dual Mechanical Seal Plans

The purpose of dual mechanical seal plans is to allow for near complete control over seal operating conditions to reduce environmental leakage, increase safety, and maximize seal life. The secondary seal is the backup in the event of an inboard seal failure and may be used to control pressure drop across seal faces. The introduction of buffer or barrier fluids are provided and monitored with plans.

Questions? Email or call 866.901.0151.

Swagelok products and assembly work are backed by our Limited Lifetime Warranty.

Plan 52 Buffer Fluid Seal Pot solution

Our seal pot solution is simple, efficient and significantly reduces safety issues and operating costs.

Plan 53A Barrier Fluid Seal Pot Pressurized by Nitrogen solution

Our Plan 53 reduces safety risks significantly and allows for refilling the seal pot while it remains online creating significant efficiencies and cost savings.

Plan 53B Barrier Fluid Pressurized by Barrier Accumulator solution

Get faster refill times and easier maintenance, along with a smaller footprint.

Plan 53C Barrier Fluid Pressurized by Piston Accumulator

Plan 53C is dual seal solution that circulates fluid between the dual seals and is optimal for applications where the seal chambers vary.

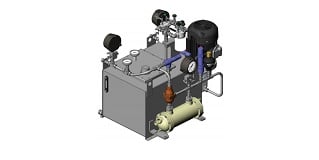

Plan 54 Barrier Fluid Pressurized by External System solution

It is a great solution for when your facility does not have a centralized seal skid serving multiple pumps.

Plan 55 Barrier Fluid Circulated by External System

Plan 55 provides cool, clean, unpressurized buffer fluid to the seal chamber.