Valves

Meeting safety requirements, reducing operating cost and minimizing unplanned downtime are essential to your job. To help ensure you are accomplishing this you need to ask some questions in order to select the proper valve. What job you need it to do? For example, is it used for on/off, flow control, directional flow, over-pressure or excess-flow protection? What are the application and system requirements? We can help walk you through this process so your team is safe, working as efficiently as possible. Better yet, we can train your team to select the right valve for your application each and every time.

All our components, including our valves, meet our stringent SQS quality requirements, so you can rest assured that you are creating a safe work environment for your team. All of our valves have lock-out tag-out (anti-trip) options to meet OSHA requirements and help keep your team safe. Higher quality also contributes to lowering your operating costs and minimizing unplanned downtime.

Ask about our API 641 and 624 low-e valve options that help you reduce fugitive emissions and meet all your regulatory standards. We offer leak detection programs to pinpoint your leaks, prioritize needed improvements and prove your case to get buy-in to make your facility best in class.

Valves are probably just one piece of your application, so consider having our Swagelok certified-experts create a subassembly for you so you can focus your resources on what you do best.

Swagelok products are backed by our Limited Lifetime Warranty.

Questions? Email or call 866.901.0151.

Ball Valves

Our signature valves come with many options from general-purpose applications to severe-service. You can rely on Swagelok ball valves to help curb leaks and fugitive emissions.

Orifice Ball Valve

Our low-e orifice ball valve can help you quickly identify and service blocked flush lines.

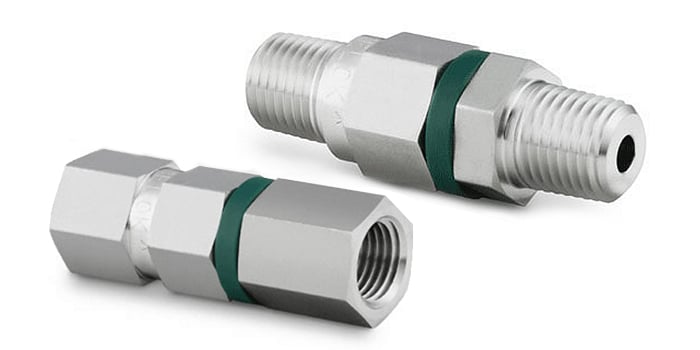

Check Valves

Control directional flow and prevent back flow with our reliable check valves. If your back-pressure exceeds the forward media pressure, the poppet will close preventing flow in the reverse direction.

Double Block and Bleed Valves

Avoid the bulk, weight, complexity, and potential leak points of assemblies made up of individual components. The compact, rigid design of the 60-Series double block and bleed valve avoids these disadvantages, saves space and significantly increases safety.

Needle Valves

Get consistent and reliable flow control from our needle valves in everything from general to severe-service applications.

Bellows Valves

Isolate system fluids and achieve reliable, leak-tight performance with Swagelok bellows valves which use a packless design and a welded seal. Bellows valves are ideal for applications where the seal to atmosphere is critical, and we offer multiple options for general and high-purity service.

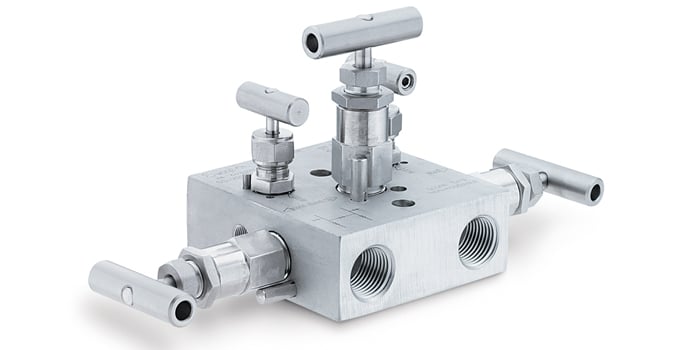

Manifold Valves

Our manifolds have a compact design reduces the footprint and weight, making them easier to install and maintain.

Relief Valves

Our relief vales deliver reliable over-pressure protection for a variety of applications, and have a simple-to-use external set pressure adjustment.

Ultrahigh-Purity Valves

Our ultrahigh-purity valves are designed to minimize or prevent the generation and collection of extremely fine particles.

Plug Valves

Our Swagelok quarter-turn plug valves have a compact design to supply full flow and positive shutoff to your fluid system.

Excess Flow Valves

Stop the uncontrolled release of system media when a downstream line ruptures with our excess flow valves.