Bite-Type Ferrules

Did you know that there are far more than 50 brands of tube fittings of various designs, dimensions, and performance on the market today? When choosing the right tube fitting, it is critical that you understand the advantages and shortfalls of various fitting designs.

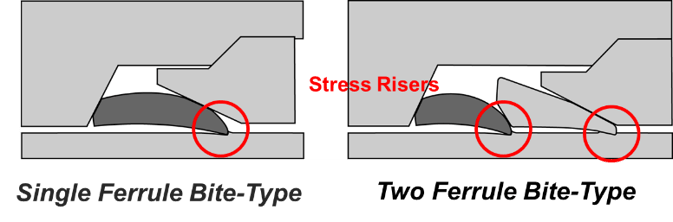

One such common design in today’s marketplace is the bite-type ferrule. Bite-type ferrules come in two varieties; single or double ferrule. Despite the number of ferrules, both types generate tube grip and create a seal on the tubing surface by “biting” into the tubing. As the fitting is tightened, bowing of the ferrule drives the nose of the ferrule into the OD of the tubing.

While a bite-type ferrule does provide some advantages over “olive design” ferrules of the 1800’s, there are significant risks with using them in modern fluid systems. First, the “bite” action of the ferrules reduces the wall thickness of the tubing. Unlike pipe (which has extra wall for the purpose of cutting threads), tube wall thickness is specifically manufactured for a particular system working pressure; reduce the wall thickness with a “bite” and you reduce the pressure rating!

Second, an uncontrolled “bite” can further damage the tube wall. Over-tightening of the fitting drives the ferrule deeper into the tube wall and effectively reducing both wall thickness and pressure containment. In extreme cases, drastic overtightening can even fully cut the tube.

Lastly, even a properly assembled bite-type ferrule is highly susceptible to vibration failure. Imagine you have a wire hanger and a wire cutter. Use the wire cutter to put a notch into the wire hanger and then begin bending it back and forth. Where will the hanger break? At the notch. Just like the notch created in the hanger by the wire cutters, the biting action of a bite-type ferrule creates a stress riser (notch) in the tubing. Over time, exposure of the stress riser to system vibration can lead to catastrophic failure of the tube wall and uncontrolled release of system media and pressure.

Want to learn more? Our Tube Fitting Essentials training course provides an in-depth look at the advantages and disadvantages of bite-type ferrules, as well as a number of other connection types commonly encountered in today’s fluid systems.

Questions on the different types of bite-types? Email or call 866.901.0151.