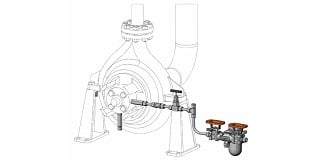

Seal Support Systems

Rotating equipment professionals have to pay attention to quality in every pump application. The selection of the proper seal, bearing motor and impeller does not guarantee long mean time between repair. Let Swagelok assist with your seal flush and seal support systems decision-making process.

Our seal support systems and fittings offer dramatic reduction in leak points, simpler installation, easier maintenance, and a significant increase in safety.

We take your application request, design it, build it and ship to meet your upgrade timeline. We have a team of seal support experts, including engineering and project support, available to make sure you get the right solution on time to meet your deadline.

We adhere to all of API 682’s standard designs, but allow the flexibility for you to customize your solution to fit your system, and you can rest assured that our mechanical seal support assemblies exceed the strictest of quality requirements and are backed by Swagelok's Limited Lifetime Warranty.

Additionally, we can get your team trained to better understand seal support systems, and how to maximize the utility of our single-fitting solutions.

Questions? Email or call 866.901.0151.

Single Mechanical Seal Plans

Plans 11-41 typically depend on redirecting fluid to or from the seal chamber by using tubing equipment and fluid treatment devices.

Dry Gas Seal Plans

Our dry gas seal plans deliver the right amount of pressure and flow to remove seal-generated heat.

Dual Mechanical Seal Plans

Dual mechanical seal plans allow for near-complete control over seal operating conditions to reduce environmental leakage, increase safety, and maximize seal life

Quench and Reservoir Plans

Quench plans provide fluid to decrease the likelihood of solid formations on the seal’s atmosphere side, helping to prevent seal wear.

Swagelok mechanical seal support systems help you reduce costs, save time, and improve safety