Double Block and Bleed Valves

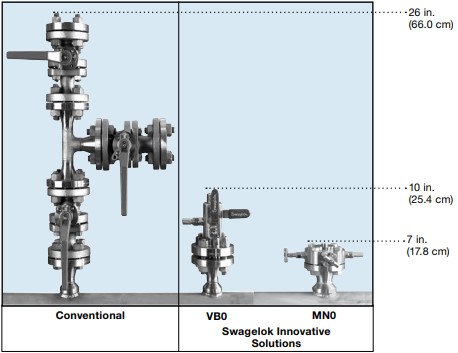

Avoid the bulk, weight, complexity, and potential leak points of assemblies made up of individual components. The compact, rigid design of the double block and bleed valve avoids these disadvantages and saves space.

Other benefits to you include:

- Ensuring positive isolation of system fluid and pressure for maintenance, equipment change-out, or calibration

- Save time during installation with a compact, high-flow design

- Factory-engineered and tested -- ready for installation

- Other configurations with Swagelok end connections available

The Swagelok process interface valve VB05 is built to meet and beat these stringent fugitive emissions requirements. This one valve can take the place of two or three valves with block and bleed and double block and bleed configurations. This allows for reduced size, weight, piping stress and potential leak paths.

Learn how to isolate industrial fluid systems with blocks valves.

Did you know?

If we ran helium as the process media for 24 hours a day, and we captured the escaping helium at Class B leak rates from this valve (our specifications for the Swagelok® Double Block and Bleed Valve) it would take two years to fill a one-liter bottle.

Concerns over climate change are driving several directives to curb greenhouse emissions from industrial plants. Studies suggest that valve leakage may account for approximately 60% of all fugitive emissions inside process plants

Questions? Email or call 866.901.0151.