Single Mechanical Seal Plans

Single mechanical seal plans (API 682 Plans 11-41) are strategic tube and pipe arrangements that circulate fluid to or from your seal chamber to preserve appropriate lubrication, pressure, temperature, and particulate conditions. The term "plan" is the preferred term by API 682 (4th edition) to indicate "an arrangement of components." Single Mechanical Seal Plans are located on the process side of the seal, with the purpose of extending seal life and keeping process fluid emissions low. These plans typically depend on redirecting fluid to or from the seal chamber by using Swagelok components, tubing and other controlling equipment.

Click on our single mechanical seal plan options below for more information.

Questions? Email or call 866.901.0151.

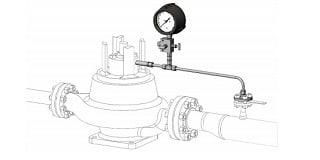

Plan 11 Flush solution

Our Plan 11 takes advantage of the benefits of tubing versus using piping, helping to reduce leaks points, decreasing installation time and complexity allowing you to keep more labor in-house.

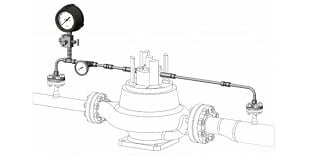

Plan 12 Flush with Strainer

Our low-weight solution offers lower installation cost and less welding. Best of all it is operator-friendly because the gauges allow you to know if the filter is clogged so you are protecting the seal from particulate.

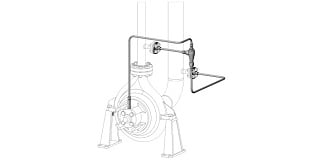

Plan 13 Flush, from Chamber to Suction solution

Because it is easy to install, requiring no special welding, our Plan 13 will save you thousands of dollars on each installation and allow you to keep this work in house.

Plan 14 Flush, Combination of Plans 11 and 13 solution

Save thousands of dollars while drastically reducing the amount of time required for installation. Since no special welding is required you can bring more labor in-house.

Plan 21 Cooled Flush solution

This system is an upgrade from traditional plans because it provides a significant reduction of weight and an operator-friendly experience due to easy-to-read in-line thermometers.

Plan 22 Cooled Flush with Strainer

When you transition to this plan your flow will improve & the weight of your overall system will drop. Plus your operators will love you because the in-line thermometers provide an easy visual reading.

Plan 23 Cooled Flush Recirculated through Seal Chamber solution

You’ll experience better flow and pump-ring efficiency because there are no restrictions in the line.

Plan 31 Flush with Cyclone Separator solution

This Plan 31 takes advantage of tubing versus using piping, reducing the number of connections, decreasing installation time and complexity allowing you to keep more labor in-house.

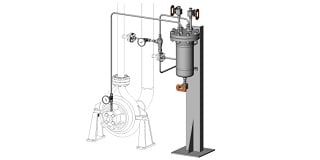

Plan 32 External Flush solution

The Plan 32 one-of-a-kind panel has a small footprint and is operator-friendly because everything is clearly labeled and at your fingertips.

Plan 41 Cooled Flush with Cyclone Separator solution

Taking advantage of tube versus using pipe, the Plan 41 reducing leak points and the potential for vibration issues.